Sun 22 Oct 2006

Turnouts

Sun 16 Jul 2006

Building my first Central Valley Model Works Turnout – Part 2

Posted by Daniel Swearingen under Layout Progress , Product Review , Track , Turnouts1 comment / Leave a comment

The continuing saga of my learning curve building Central Valley Model Works� turnout kits. In part one I did the basic assembly.

Now that I’ve added some track around my turnout I can actually run trains over it. The turnout works very well but I did not do a perfect job assembling it.� I’m trying to be a very harsh critic of myself because several turnouts on the layout are in tough to reach places and I need to be very clear on proper technique before I build them.

Few things will ruin the enjoyment of your layout more than a turnout in the back corner that keeps derailing everything.

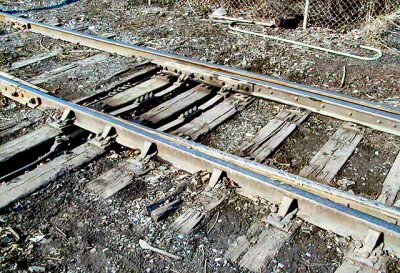

The main things I did wrong are not get the rails tightly enough around the frog and I did not snug the guard rails close enough to the stock rails.

Using an NMRA standards gauge you can see that the track gauge is correct but the width of the flangeway is not correct. For those not familiar with this tool the tabs highlighted in red show how wide the flangeway should be.

Given the way the frog casting works, snugging up the guard rail (the black plastic rail on the left) will be the easy fix.

One thing to watch is to make sure that the frog rails (the rails that are attached in a “V”) are pushed as far forward into the frog casting as possible. However, this can be taken too far since the geometry is such that if pushed too� far forward� the track gauge will become too narrow.

An� easy fix: make sure the closure rails (by the arrow on the right)

are really tight to the frog casting. Note that the closure rail on the left of the frog (to the left of the RIGHT arrow) is loose.� The closure rail on the right of the frog is pretty good.

Despite these obvious flaws the turnout works flawlessly (if a bit bumpy for some pieces of rolling stock) so I have to admit that the Central Valley design seems to be quite forgiving.

Sat 4 Mar 2006

Building my first Central Valley Model Works Turnout – Part 1

Posted by Daniel Swearingen under Layout Progress , Product Review , Track , Turnouts[6] comments / Leave a comment

Ok, so far this first turnout is kicking my ass. I’ll produce a real “how to build these turnouts” article — when I really know to build one of these turnouts. Right now, I’m severely learning. Think of this as a “still clinging to the cliff” kind of report although I’m still having fun and I’m still happy about choosing the Central Valley turnout kits.

Central Valley Model Works (CVMW) has been around since the late 1940’s. However, their CVT system of styrene tie strips and turnout kits is relatively new. I’m building most of my track using Micro Engineering code 83 flex track. Code 83 you say? Yes, I have some old Rivarrosi and IHC engines that I actually like, and code 70 is too low for their (way too big) flanges so code 83 it is – good enough.

For turnouts I originally intended to use Walthers/Shinohara code 83 #4’s – these are excellent turnouts but were completely out of stock for the foreseeable future during the end of 2005 when I was putting all my materials together. I procrastinate enough at the best of times and having any real excuse to stop forward progress is simply too risky so I shopped around for an immediately available alternative. The CVT turnouts had been on my short list and they were available. I ordered straight from CVMW and they arrived quickly.

The pros, cons, and costs of the CVT turnouts are obvious:

Pro: great detail – museum quality looks.

Con: you need to build them yourself and I feel it’s fair to say that they are one notch more difficult than the normal way one would scratch build a turnout and obviously way more work than a pre-built turnout.

Cost: very comparable with other turnouts. Not really a factor in the decision.

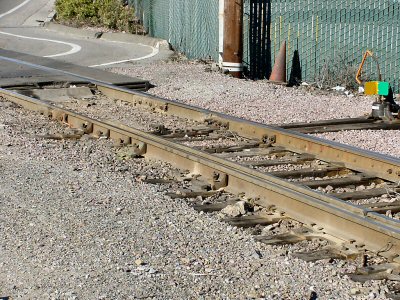

I picked a spot on my layout to lay the first turnout.

An easily accessible simple siding on the mainline. The CVT instructions (yes, I actually read them) say to start by gluing down the tie strip onto the layout. However since this was my first one I chose to do a quite a bit of dry fitting on the workbench before doing anything on the layout.

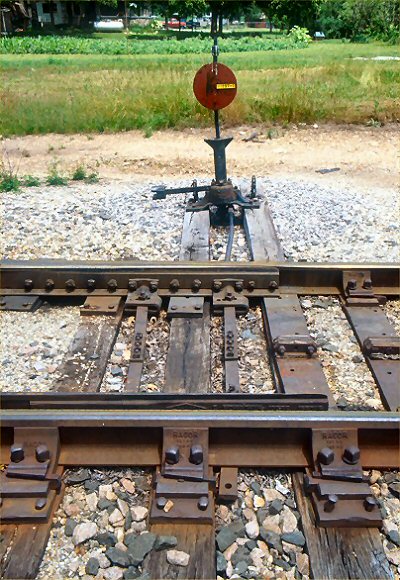

I made a drilling template out of ¼ masonite and drilled the “throw” hole and holes for feeder wires. Then glued the tie block down with contact cement and glued down a small piece of roadbed to be the foundation for the switch stand.

I’d love to say “then I just attached the rails and away we go” but there has been a lot of learning. Central Valley recommends barge cement diluted with MEK to attach the rails. I tried it and this is a really good recommendation — but there is still some art involved.

After some work I got my first turnout installed and working.

I’m using Tortoise switch machines and I’m using 1/16” square brass rod to throw the turnout.